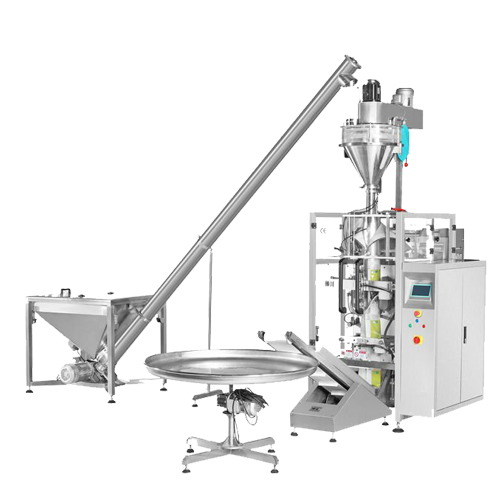

AUTOMATIC ATTA PACKING MACHINE 10kg

उत्पाद विवरण:

- शोर का स्तर 1

- फिलिंग रेंज upto 10KG

- एप्लीकेशन Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system.

- उपयोग 6KWA

- विशेषताएँ Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system. Pneumatically operated vertical sealing system best suitable for heat sealable laminates with stroke adjustment facilities. Bon Varo Italy brand Geared Motor Omron Japan PID Temperature controllers AC Drive For auger Stellar - DELTA/ INVT Food Grade 304 Stainless steel contact parts with covering.

- बिजली की आपूर्ति 280 volte

- टाइप करें

- अधिक देखने के लिए क्लिक करें

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- upto 10KG

- 1 YEAR

- STAINLESS STEEL

- 1

- वोल्ट (v)

- Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system.

- वाट (w)

- फुट (फुट)

- 280 volte

- , ,

- पीसी/घंटा

- किलोग्राम (kg)

- Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system. Pneumatically operated vertical sealing system best suitable for heat sealable laminates with stroke adjustment facilities. Bon Varo Italy brand Geared Motor Omron Japan PID Temperature controllers AC Drive For auger Stellar - DELTA/ INVT Food Grade 304 Stainless steel contact parts with covering.

- 6KWA

व्यापार सूचना

- DELHI

- प्रति सप्ताह

- दिन

- Yes

- * PACK POWDER ITEMS UPTO 5KG TO 10KG IN CENTER CEALING POUCH. * PACKING SPEED IS 17 BAGS PER MINUTE IN 10KG BAGS

- , , , , , , , ,

- , , , , , , , , , , , , , , , , , , , , , , , ,

- ISO CERTIFIED

उत्पाद वर्णन

Pneumaticallyoperatedverticalsealingsystembestsuitableforheatsealable laminates with stroke adjustmentfacilities.

Bon Varo Italy brand GearedMotor

Omron Japan PID Temperature controllers

ACDrive For auger Stellar - DELTA/ INVT

FoodGrade304Stainlesssteelcontactpartswithcovering.

1.Bag Draw downMechanism

Packagingmaterialdrawdownwithbelts,drivenseparatelybyMotor.

Self-aligningcouplingssupportdrivebeltsinbettermotion.

Belt pressure adjustedpneumatically.

2.Perforation or BatchAssembly.

Pneumaticallyactivatedknifeforcuttingthestreameratdesiredcount.

ThecountiscontrolleddigitallybyPLC.

Theactivationofcoilforactivationofcylinderistransistorbased.

Unitcylinderusedforactionofperforation.

Horizontal Sealing Jaw forlaminates.

3.SetofFront&RearSealingJawscompletewithpneumatically activatedknife, heaters andthermo couple.

Standarddesign is V-groove in 2mmpitch.

TheintegratedtooliscapableofachievingBottomSealandtheTopSealofthenext bag in a singlecycle.

4.Longitudinal Sealing Jawforlaminates.

LongitudinalSealingtoolsuitableforverticalseal.

Jaw width15mm.

Sealingtooliscompletewithcartridgeheaterandthermo couple.

5.Pouch/Bag FormingAssembly.

Every Individual Paper Setting will contain:

Individual Top and BottomPlate.

Former Pipe and PouchFormer/Collar.

6.Machine ControlPanel

Powder coated full size controlpanel.

The MMI (operatorInterface)with keyboard, temperatureindicators, controllers, andothermachinecontrolbuttonsandemergencystopswitches.

Thepanelisprotectedagainstpoorpowersupplyqualityorinotherwordsthe machinestopsincaseofoverload,undervoltageandsinglephasingandsurges.

Allwiresandterminalsarenumberedinsidethepanel.

Thetemperaturecontrolsandsettingareprovidedintheoperatorinterface.

1.SetofFront&RearSealingJawscompletewithpneumatically activatedknife, heaters andthermo couple.

Standarddesign is V-groove in 2mmpitch.

TheintegratedtooliscapableofachievingBottomSealandtheTopSealofthenext bag in a singlecycle.

2.Longitudinal Sealing Jawforlaminates.

LongitudinalSealingtoolsuitableforverticalseal.

Jaw width15mm.

Sealingtooliscompletewithcartridgeheaterandthermo couple.

3.Pouch/Bag FormingAssembly.

Every Individual Paper Setting will contain:

Individual Top and BottomPlate.

Former Pipe and PouchFormer/Collar.

4.Machine ControlPanel

Powder coated full size controlpanel.

The MMI (operatorInterface)with keyboard, temperatureindicators, controllers, andothermachinecontrolbuttonsandemergencystopswitches.

Thepanelisprotectedagainstpoorpowersupplyqualityorinotherwordsthe machinestopsincaseofoverload,undervoltageandsinglephasingandsurges.

Allwiresandterminalsarenumberedinsidethepanel.

Thetemperaturecontrolsandsettingareprovidedintheoperatorinterface.

5.AugerFillingSystemServoMotorApplication:

Lightinweightforeaseininstallation.

Inbuiltinternalrevolverprovidedforaccuracyofpositioningofaxis.

Drivesusedformotorareloadedwithfeatureofautophasing.

Clampingresistorsareusedforinstantbreaking.

BuiltinEMCFilterforreductioninnoiseeffect.

Inbuiltstirrerusedforstirringofpowdertoavoidformationoflumps.

6.Bag Type:Centre sealed pillowtype

7.Packagingmaterial:HeatSealablelaminatedpolyesterorPE.

8.Speeds &Accuracies:

(Dependinguponthephysicalandflowcharacteristicsoftheproduct) @ filling accuracyof+/-1%)

PPM 5kg to 10kg @ 15-25pouches permin

The above stated speed can be met subject to:-

a)Uninterrupted productflow.

b)Uniformityofthemachinetoaneffectiveairpressuresystem.

c)Connectionofthemachinetoaneffectiveairpressuresystem.

d)StrictMaintenanceofthemachineasperourInstructionManual.

The above stated accuracies can be met subject to:-

a)Feedingoftheproductataconstantratesoastomaintainthelevelinsidethe machinehopper.

b)CleaningoftheAugerScrew&Pipeatregulartimeintervals.

c)Constant Bulkdensity.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+