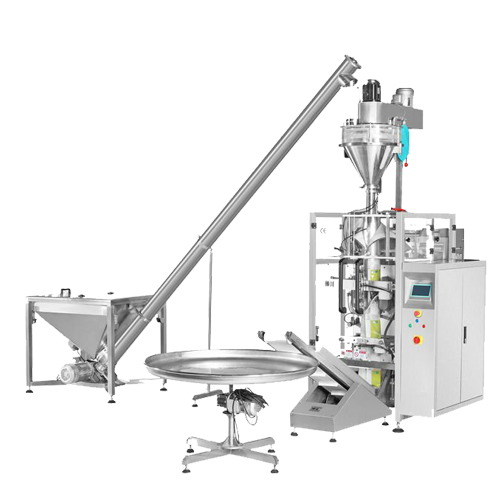

AUTOMATIC ATTA PACKING MACHINE 10kg

Product Details:

- Application Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system.

- Noise Level 1

- Filling Range upto 10KG

- Power Supply 280 volte

- Usage 6KWA

- Features Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system. Pneumatically operated vertical sealing system best suitable for heat sealable laminates with stroke adjustment facilities. Bon Varo Italy brand Geared Motor Omron Japan PID Temperature controllers AC Drive For auger Stellar - DELTA/ INVT Food Grade 304 Stainless steel contact parts with covering.

- Type Filling Machine

- Click to View more

AUTOMATIC ATTA PACKING MACHINE 10kg Price And Quantity

- 890000.0 INR/Piece

- 1 Piece

AUTOMATIC ATTA PACKING MACHINE 10kg Product Specifications

- 280 Volt (v)

- 1000 Pcs/hr

- 1

- STAINLESS STEEL

- Filling Machine

- Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system.

- PLC Control

- Heat Sealing

- 546 Foot (ft)

- 1 YEAR

- Yes

- 280 volte

- Highly Efficient, Less Power Consumable, Heavy Duty Machine, Durable, Rust Proof

- 6KWA

- Electric

- 6000 Watt (w)

- Automatic

- Equipped with: PLC Controller DELTA/ INVT HMI (7.3 Inch Touch Screen Panel)- DELTA/ INVT Main Servo Motor - DELTA/ INVT Pulling servo Motor - DELTA/ INVT Mechanically operated longitudinal and cross sealing jaw assemblies suitable for Heat Sealable laminates. Pneumatic(Pneumax Italy) engage/dis-engage system with adjustable pressure for belt draw-off system. Pneumatically operated vertical sealing system best suitable for heat sealable laminates with stroke adjustment facilities. Bon Varo Italy brand Geared Motor Omron Japan PID Temperature controllers AC Drive For auger Stellar - DELTA/ INVT Food Grade 304 Stainless steel contact parts with covering.

- Other

- upto 10KG

- 1000 Kilograms (kg)

- White

AUTOMATIC ATTA PACKING MACHINE 10kg Trade Information

- DELHI

- Others

- 1 Piece Per Week

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- * PACK POWDER ITEMS UPTO 5KG TO 10KG IN CENTER CEALING POUCH. * PACKING SPEED IS 17 BAGS PER MINUTE IN 10KG BAGS

- Central America, North America, South America, Asia, Australia, Eastern Europe, Western Europe, Middle East, Africa

- Meghalaya, Andhra Pradesh, All India, Central India, West India, Karnataka, Kerala, Lakshadweep, Jammu and Kashmir, Madhya Pradesh, Nagaland, Rajasthan, Chandigarh, Jharkhand, Odisha, Punjab, Assam, Arunachal Pradesh, Chhattisgarh, Sikkim, Tamil Nadu, Telangana, Uttar Pradesh, Uttarakhand, West Bengal

- ISO CERTIFIED

Product Description

Pneumaticallyoperatedverticalsealingsystembestsuitableforheatsealable laminates with stroke adjustmentfacilities.

Bon Varo Italy brand GearedMotor

Omron Japan PID Temperature controllers

ACDrive For auger Stellar - DELTA/ INVT

FoodGrade304Stainlesssteelcontactpartswithcovering.

1.Bag Draw downMechanism

Packagingmaterialdrawdownwithbelts,drivenseparatelybyMotor.

Self-aligningcouplingssupportdrivebeltsinbettermotion.

Belt pressure adjustedpneumatically.

2.Perforation or BatchAssembly.

Pneumaticallyactivatedknifeforcuttingthestreameratdesiredcount.

ThecountiscontrolleddigitallybyPLC.

Theactivationofcoilforactivationofcylinderistransistorbased.

Unitcylinderusedforactionofperforation.

Horizontal Sealing Jaw forlaminates.

3.SetofFront&RearSealingJawscompletewithpneumatically activatedknife, heaters andthermo couple.

Standarddesign is V-groove in 2mmpitch.

TheintegratedtooliscapableofachievingBottomSealandtheTopSealofthenext bag in a singlecycle.

4.Longitudinal Sealing Jawforlaminates.

LongitudinalSealingtoolsuitableforverticalseal.

Jaw width15mm.

Sealingtooliscompletewithcartridgeheaterandthermo couple.

5.Pouch/Bag FormingAssembly.

Every Individual Paper Setting will contain:

Individual Top and BottomPlate.

Former Pipe and PouchFormer/Collar.

6.Machine ControlPanel

Powder coated full size controlpanel.

The MMI (operatorInterface)with keyboard, temperatureindicators, controllers, andothermachinecontrolbuttonsandemergencystopswitches.

Thepanelisprotectedagainstpoorpowersupplyqualityorinotherwordsthe machinestopsincaseofoverload,undervoltageandsinglephasingandsurges.

Allwiresandterminalsarenumberedinsidethepanel.

Thetemperaturecontrolsandsettingareprovidedintheoperatorinterface.

1.SetofFront&RearSealingJawscompletewithpneumatically activatedknife, heaters andthermo couple.

Standarddesign is V-groove in 2mmpitch.

TheintegratedtooliscapableofachievingBottomSealandtheTopSealofthenext bag in a singlecycle.

2.Longitudinal Sealing Jawforlaminates.

LongitudinalSealingtoolsuitableforverticalseal.

Jaw width15mm.

Sealingtooliscompletewithcartridgeheaterandthermo couple.

3.Pouch/Bag FormingAssembly.

Every Individual Paper Setting will contain:

Individual Top and BottomPlate.

Former Pipe and PouchFormer/Collar.

4.Machine ControlPanel

Powder coated full size controlpanel.

The MMI (operatorInterface)with keyboard, temperatureindicators, controllers, andothermachinecontrolbuttonsandemergencystopswitches.

Thepanelisprotectedagainstpoorpowersupplyqualityorinotherwordsthe machinestopsincaseofoverload,undervoltageandsinglephasingandsurges.

Allwiresandterminalsarenumberedinsidethepanel.

Thetemperaturecontrolsandsettingareprovidedintheoperatorinterface.

5.AugerFillingSystemServoMotorApplication:

Lightinweightforeaseininstallation.

Inbuiltinternalrevolverprovidedforaccuracyofpositioningofaxis.

Drivesusedformotorareloadedwithfeatureofautophasing.

Clampingresistorsareusedforinstantbreaking.

BuiltinEMCFilterforreductioninnoiseeffect.

Inbuiltstirrerusedforstirringofpowdertoavoidformationoflumps.

6.Bag Type:Centre sealed pillowtype

7.Packagingmaterial:HeatSealablelaminatedpolyesterorPE.

8.Speeds &Accuracies:

(Dependinguponthephysicalandflowcharacteristicsoftheproduct) @ filling accuracyof+/-1%)

PPM 5kg to 10kg @ 15-25pouches permin

The above stated speed can be met subject to:-

a)Uninterrupted productflow.

b)Uniformityofthemachinetoaneffectiveairpressuresystem.

c)Connectionofthemachinetoaneffectiveairpressuresystem.

d)StrictMaintenanceofthemachineasperourInstructionManual.

The above stated accuracies can be met subject to:-

a)Feedingoftheproductataconstantratesoastomaintainthelevelinsidethe machinehopper.

b)CleaningoftheAugerScrew&Pipeatregulartimeintervals.

c)Constant Bulkdensity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+